Welcome To Huida

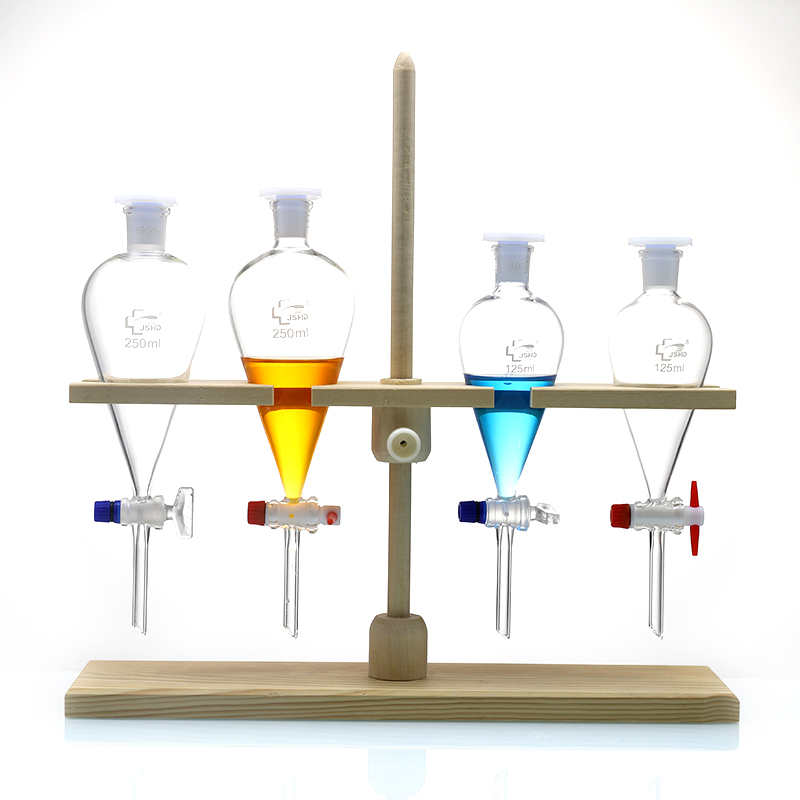

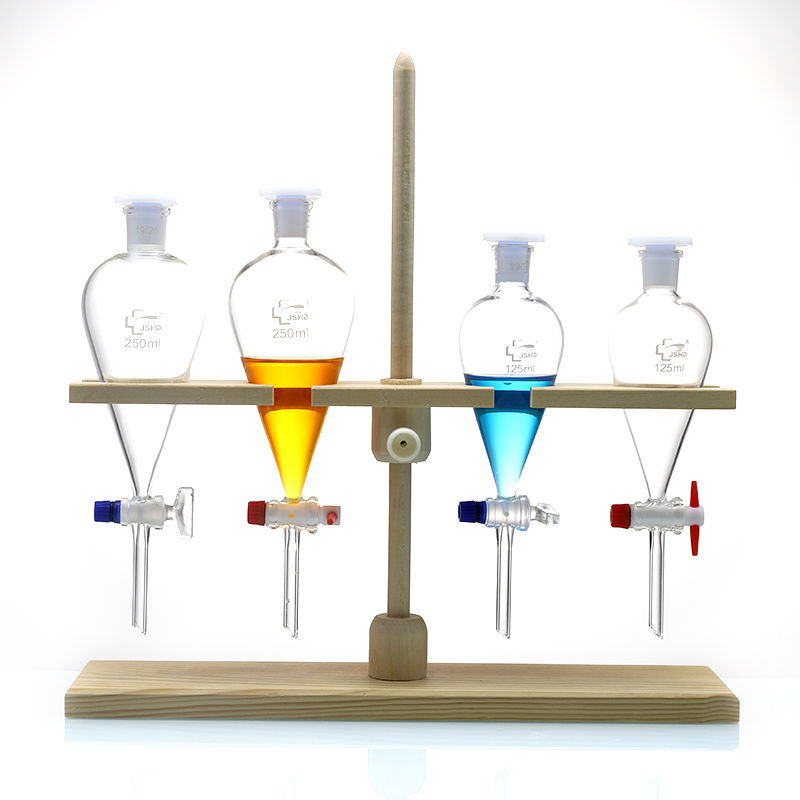

Separatory FunnelSquib pear shape With ground – in glass stopper and GLASS/PTFE stopcock

Laboratory Glassware

Separatory Funnel

Separatory Funnel Introduction

A separatory funnel, also known as separation funnel, separating funnel,or collquially sep funnel, is a piece of laboratory glassware used in liquid-liquid extractions to separate (partition) the components of a mixture into two immiscible solvent phases of different densities.

About Separatory Funnel

Product Specification

The dimensions are all measured by hand, so there may be some errors. Please contact us for the specific freight.

|

1543/8543 |

Separatory Funnel Squib pear shape With ground – in glass stopper and GLASS/PTFE stopcock |

|

|

Capacity(ml) |

Dia. of stem × Length (mm) |

Length(mm) |

|

10 |

8×60 |

126 |

|

20 |

8×60 |

135 |

|

60 |

10×70 |

220 |

|

125 |

10×70 |

260 |

|

250 |

11×70 |

290 |

|

500 |

12×70 |

330 |

|

1000 |

12×70 |

400 |

Product Details

High borosilicate glass

Adopt high borosilicate glass, high temperature resistance, strong and durable.

Smooth surface

The surface of the bottle body is smooth, no protruding feeling, beautiful and generous.

Borosilicate glass has excellent chemical and physical properties.The linear expansion cofficient of the primary hydrolyzable glass is 3.3 for applications requiring excellent chemical resistance and thermal resistance (including thermal shock resistance), as well as high mechanical stability. It is a typical glass for chemical equipment.

Safety concerns

The largest risk when using a separating funnel is that of pressure build-up. Pressure accumulates during mixing if a gas evolving reaction or physical change occurs. This problem can be easily handled by simply opening the stopper at the top of the funnel routinely while mixing. More standard procedure is to invert the separating funnel upside down, and open the stopock to release the pressure, a step done repeatedly known as 'venting'. This should be done with the tip of the funnel pointed away from the body.

Product Parameters

|

BOROSILICATE GLASS |

|

|

BORO3.3 |

|

| SiO2 Content | >80% |

| Strain Point | 520°C |

| Annealing Point | 560°C |

| Softening Point | 820°C |

| Refractive Index | 1.47 |

| Light Transmission(2mm) | 0.92 |

| Elastic Modulus | 67KNmm-2 |

| Tensile Strength | 40-120Nmm-2 |

| Glass stress Optical Coefficient | 3.8*10-6mm2/N |

| Processing Temperature(104dpas) | 1220°C |

| Linear Coefficient of Expansion(20-300°C) | 3.3*10-6K-1 |

| Density(20°C) | 2.23gcm-1 |

| Specific Heat | 0.9jg-1K-1 |

| Thermal Conductivity | 1.2Wm-1K-1 |

| Hydrolytic Resistance(ISO 719) | Grade 1 |

| Acid Resistance(ISO 185) | Grade 1 |

| Alkali Resistance(ISO 695) | Grade 2 |

| Thermal Shock Resistance Rod6*30mm | 300°C |

Scope Of Application

Medical field

Classroom equipment

Laboratory

Chemical industry

Send your message to us:

Products categories

Why Choose Us

Yancheng Huida Glass Instrument Co., Ltd. is the experienced manufacturer, mainly produces high quality laboratory glassware and other general labware. The band of “YCHD” boiling glass series and volumetric measuring instruments are well-known all over the world.