Welcome To Huida

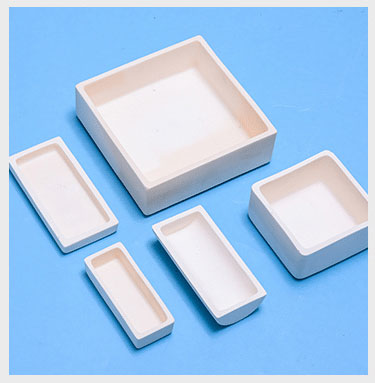

Laboratory High Temperature Alumina Ceramic Combustion Boat

Product Specification

|

Code |

Length (mm) |

Rim width (mm) |

Bottom width (mm) |

Height (mm) |

|

C-94 |

60 |

10 |

6 |

8 |

|

C-95 |

72 |

11 |

6 |

9 |

|

C-96 |

77 |

12 |

7 |

9 |

|

C-97 |

88 |

13 |

8 |

10 |

|

C-98 |

95 |

15 |

9 |

10 |

|

C-99 |

97 |

17 |

10 |

11 |

Product information

1.Overview and use:

These products are made of common chemical porcelain as raw materials, and are formed by the process of grouting or hollow grouting method. They are suitable for the analysis of carbon and sulfur content in steel and iron samples. Porcelain ark is suitable for the test of volatiles from light mineral samples. Such as charcoal, can be used to replace the volatile crucible.

2. Use method:

The combustion tube and the combustion boat must be used in a complete set. The general combustion tube is used as the furnace tube in the tubular furnace. The outer part of the tube is made of charcoal rod.

When in use, weigh the sample into the combustion boat, into the combustion tube, through the high temperature oxygen flow will be the ore sample combustion, and then the combustion of gas analysis, determine the content of carbon and sulfur in a certain weight of ore sample.

Product Details

|

Feature |

Combustion Boats |

|

Color |

Ivory |

|

Material |

Alumina ceramic |

|

Size |

Customerized |

|

Advantage |

High Strength; High Hardness; Insulation; High Temperature Resistance; Oxidation Resistance; Corrosion Resistance; Abrasion Resistance...... |

High Temperature Resistance

It has the characteristics of high melting and boiling point and can be used at high temperature without being affected.

Electrical Insulating

Insulator has high resistivity at room temperature. It can be used in equipment requiring insulation.

Function

1. All products will have been strictly quality checked in house before packing

2. With complete specifications, smooth internal surface, bright

Product Parameters

|

95%/99%/99.7% Al2O3 Ceramic Material Parameters |

||||

|

Item |

Test Condition |

95% Al2O3 Ceramic |

99% Al2O3 Ceramic |

99.7% Al2O3 Ceramic |

|

Bulk Density (g/cm³) |

>3.6 |

3.89 |

3.96 |

|

|

Maximum Use Temp(℃) |

1450 |

1600 |

1650 |

|

|

Water Absorption(%) |

0 |

0 |

0 |

|

|

ROHS Hardness |

≥85 |

≥89 |

≥89 |

|

|

Flexural Strength MPa(psi×10³) |

20℃ |

358(52) |

550 |

550 |

|

Compressive Strength MPa(psi×10³) |

20℃ |

2068(300) |

2600(377) |

2600(377) |

|

Fracture Toughness Mpa m½ |

K(l c) |

4-5 |

5.6 |

6 |

|

Thermal Expansion Coefficient(1×10-6/℃) |

25-1000℃ |

7.6 |

7.9 |

8.2 |

|

Thermal Conductivity Coefficient(W/m°K) |

20℃ |

16 |

30.0 |

30.4 |

|

Thermal Shock Resistance(℃) |

△Tc |

250 |

200 |

200 |

|

Dielectricity Constant |

1MHz.25℃ |

9 |

9.7 |

9.7 |

|

Dielectric Strength (ac-kV/mm)(ac V/mil) |

8.3(210) |

8.7(220) |

8.7(220) |

|

|

Volume Resistivity (ohm-cm) |

100℃ |

>1013 |

>1014 |

>1014 |

Advantage of Our Company

1. Professional medical products manufacture for more than 10 years

2. High quality with competitive price

3. Independent Design and Outstanding Sales Team

4. Large Supply Ability

5. Excellent after-Sales service

Send your message to us:

Products categories

Why Choose Us

Yancheng Huida Glass Instrument Co., Ltd. is the experienced manufacturer, mainly produces high quality laboratory glassware and other general labware. The band of “YCHD” boiling glass series and volumetric measuring instruments are well-known all over the world.